OEM#: 00-877298-01New OEM Original Outright

PUSHER CABLE FOR 5 IN CASTER by OEC Medical Systems (GE Healthcare)

Your price:

$27.47 each $29.41 Savings: $1.94 (7%)

OEM#: 00-877298-01PUSHER CABLE FOR 5 IN CASTER by OEC Medical Systems (GE Healthcare)

New OEM Original Outright

Your price:

$27.47 each

$29.41 Savings: $1.94 (7%)

Asset Information

Are you an existing customer? Sign in to access your account.

ADD TO LIST

Product Overview

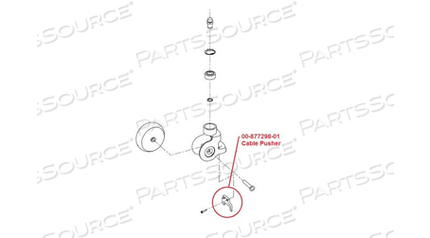

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

Features

- Has good dimensional stability

- Easy to mount

- High impact strength

- High strength and lightweight

- Clean and free from flashes

Technical Specs

P/N: 00-877298-01 Key Specs

Item

PUSHER CABLE FOR 5 IN CASTER

OEM

OEC Medical Systems (GE Healthcare)

OEM #

00-877298-01

Condition

New OEM Original

Returnable

No

Warranty

90 Day

Fitments

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

- OEC Medical Systems (GE Healthcare)

- 9600

- 9800

- 9900

- 9900 ELITE

- 6800 MINIVIEW

- 2800 UROVIEW

- ELITE

- ELITE CFD

Product Overview

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

Features

- Has good dimensional stability

- Easy to mount

- High impact strength

- High strength and lightweight

- Clean and free from flashes

Technical Specs

P/N: 00-877298-01 Key Specs

Item

PUSHER CABLE FOR 5 IN CASTER

OEM

OEC Medical Systems (GE Healthcare)

OEM #

00-877298-01

Condition

New OEM Original

Returnable

No

Warranty

90 Day

Fitments

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

- OEC Medical Systems (GE Healthcare)

- 9600

- 9800

- 9900

- 9900 ELITE

- 6800 MINIVIEW

- 2800 UROVIEW

- ELITE

- ELITE CFD

Product Overview

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

Features

- Has good dimensional stability

- Easy to mount

- High impact strength

- High strength and lightweight

- Clean and free from flashes

Technical Specs

P/N: 00-877298-01 Key Specs

Item

PUSHER CABLE FOR 5 IN CASTER

OEM

OEC Medical Systems (GE Healthcare)

OEM #

00-877298-01

Condition

New OEM Original

Returnable

No

Warranty

90 Day

Fitments

The cable pushers are used in the workstation assembly where they are installed on the lower part of the cart. This pusher blade is made of Low Density Polyethylene (LDPE 640I) material which is a general purpose liner resin for thin gauge applications that require good drawdown and excellent toughness. Plus the Low Density Polyethylene (LDPE 640I) is abrasion resistance, chemical resistance, impact resistance and is a good surface finish. Usually, the purpose of the cable pusher is to prevent the tangling or pinching of wires and cables routed on the floor. During motion,the pusher comes in contact with the objects first to avoid direct interference with the main object by pushing the obstacles

- OEC Medical Systems (GE Healthcare)

- 9600

- 9800

- 9900

- 9900 ELITE

- 6800 MINIVIEW

- 2800 UROVIEW

- ELITE

- ELITE CFD