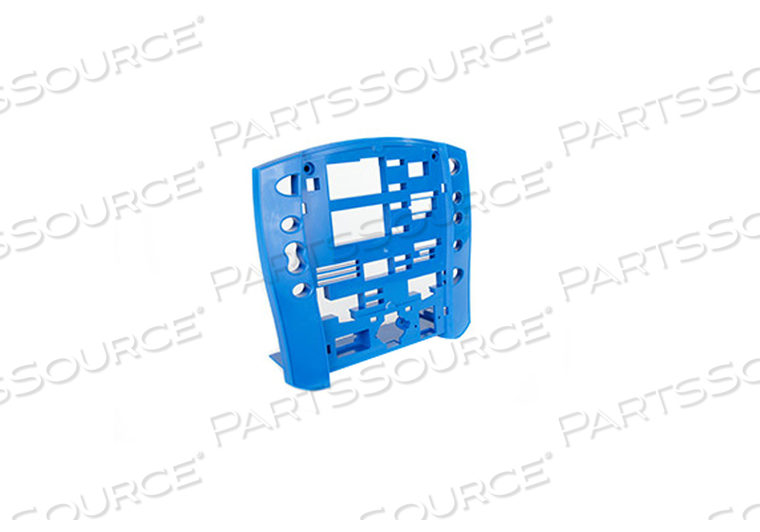

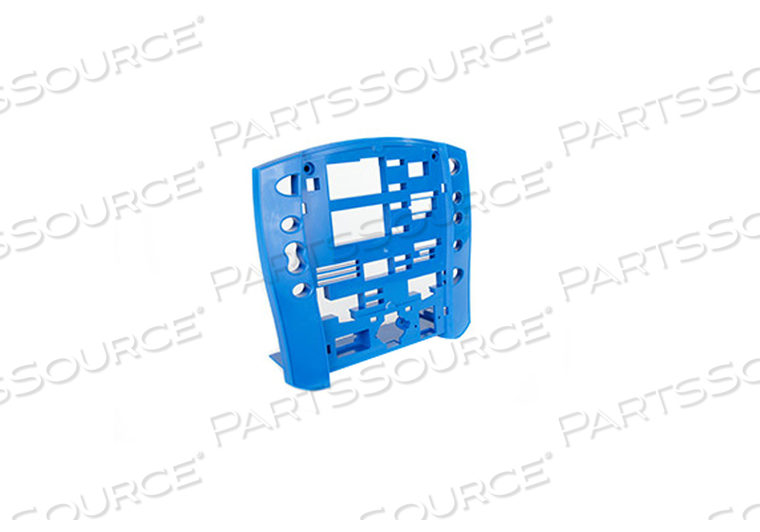

FRONT HOUSING, PLASTIC

Replaces GE Medical Systems Information Technology (GEMSIT) 702190FRONT HOUSING, PLASTIC

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.

- Excellent Temperature Resistance, Moisture Resistance, Increased Lifespan

- Low Environmental Impact, Enhanced Durability, Easily Portable, Lightweight, Easy to Clean and Reusable

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.

- Excellent Temperature Resistance, Moisture Resistance, Increased Lifespan

- Low Environmental Impact, Enhanced Durability, Easily Portable, Lightweight, Easy to Clean and Reusable

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.

- Excellent Temperature Resistance, Moisture Resistance, Increased Lifespan

- Low Environmental Impact, Enhanced Durability, Easily Portable, Lightweight, Easy to Clean and Reusable

The plastic housing front is used in the patient monitoring machines, computed tomography (ct) machines, magnetic resonance imaging (mri) machines and many other digital imaging (di) machines. The plastic alloy material used for the cover and trim has good mechanical properties like high tensile strength and good impact resistance which ensures an increased lifespan for them. The parts are free from any burrs and sharp edges which enhances the safety aspect of the part. The product is made up of high-quality material, that has very good mechanical, thermal, electrical and chemical properties. It can be able to withstand a wide range of temperature and pressure. It is free from dust, burrs, sharp edges, surface blemishes, sink marks and flash. The ge product is an innovation and technology which fits well into versatile customer needs. The product is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, quality assurance (qa) seal and shipment details.